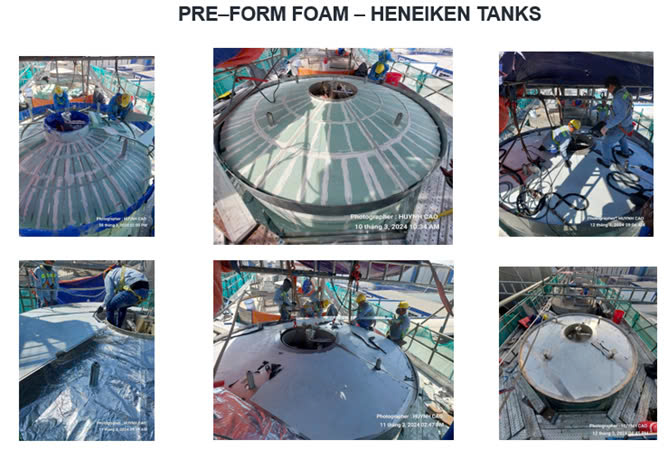

09 Nov Custom Steel Cladding Solutions for Heineken

Project for Replacement of Metal Cladding for Beer Tank Insulation at Heineken Brewery Vung Tau

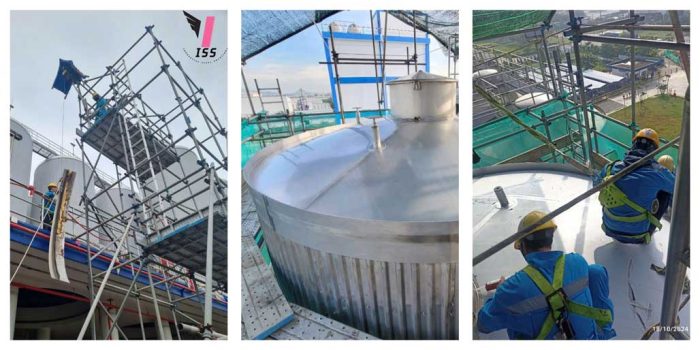

Innovative Steel Solutions Co., Ltd (ISS) is proud to have successfully completed the replacement of SS304 stainless steel cladding for the torispherical tops of 12 beer tanks at Heineken Brewery Vung Tau. This marks a significant milestone for ISS in providing high-quality mechanical fabrication services for the beverage industry in particular and the food processing sector in general.

-

Project Overview

ISS provided a comprehensive service package, including design, fabrication at our in-house workshop, and on-site welding and assembly of SS304 stainless steel insulation cladding for 12 beer tanks at Heineken Brewery Vung Tau. The use of SS304 material was an optimal choice, offering both aesthetic appeal and excellent corrosion resistance while effectively protecting the insulation layer from environmental factors, ensuring stable internal temperatures for the tanks.

-

Scope of Work

We conducted meticulous design calculations to optimize the torispherical tops, minimizing weld seams within the standard dimensions of available steel sheets. CNC laser cutting was employed to cut SS304 steel plates based on the finalized designs.

On-site assembly and welding were critical components of this project, demanding high technical expertise. The weld seams required precision to prevent deformation on thin 3mm steel sheets while avoiding damage to the PIR layer beneath, ensuring long-term efficiency of the insulation system.

Our team of welders is certified by the renowned organization Det Norske Veritas (DNV), which ensures we employ skilled professionals capable of meeting the most stringent industry requirements.

At ISS, we prioritize quality above all. Following ISO 3834-2 standards, our process includes rigorous material inspections, welder certifications, welding procedures, NDT quality checks, and thorough completion reports. This commitment enables us to deliver high-quality welds that contribute to the durability and safety of every project. Enhancing product and service quality remains our top priority.

-

Commitment to Quality and Safety

For Innovative Steel Solutions Co., Ltd., each project is more than a product—it is a testament to our dedication to quality and safety.

With strict adherence to ISO 3834-2 standards, we ensure that every stage of the process—from site surveys and fabrication to installation—is carried out with professionalism and efficiency. This minimizes risks during welding and assembly while meeting the most stringent technical requirements. Additionally, we conduct regular evaluations and inspections to ensure every detail is up to standard before project handover.

Our unwavering focus on quality and safety drives us to deliver exceptional results, ensuring the sustainability and reliability of all the projects entrusted to us.

Contact ISS

If you require more information or have any inquiries regarding the project, do not hesitate to contact Innovative Steel Solutions Co., Ltd (ISS). We are always ready to advise and offer the best solutions for all your needs in metal fabrication and industrial welding.

- Website: issco.ltd

- Email: kha.ho@issco.ltd

- Phone: +84 (0)989 050 035

- Factory Address: Road No. 5, Dong Xuyen Industrial Park, Rach Dua Ward, Vung Tau City, BRVT Province

- Office Address: 475-477 2/9 Street, Thang Nhat Ward, Vung Tau City, BRVT Province

No Comments