STEEL SOLUTIONS

ISS complies with ISO 3834-2: Comprehensive quality requirements. ISO 3834-2 applies to organizations with complex welding operations requiring extensive quality controls, designed for organizations that carry out complex and critical welding processes. It is often adopted in industries where the integrity of welded joints is vital for safety and performance, such as aerospace, pressure vessel manufacturing, structural steel, shipbuilding, energy, and oil and gas industries.

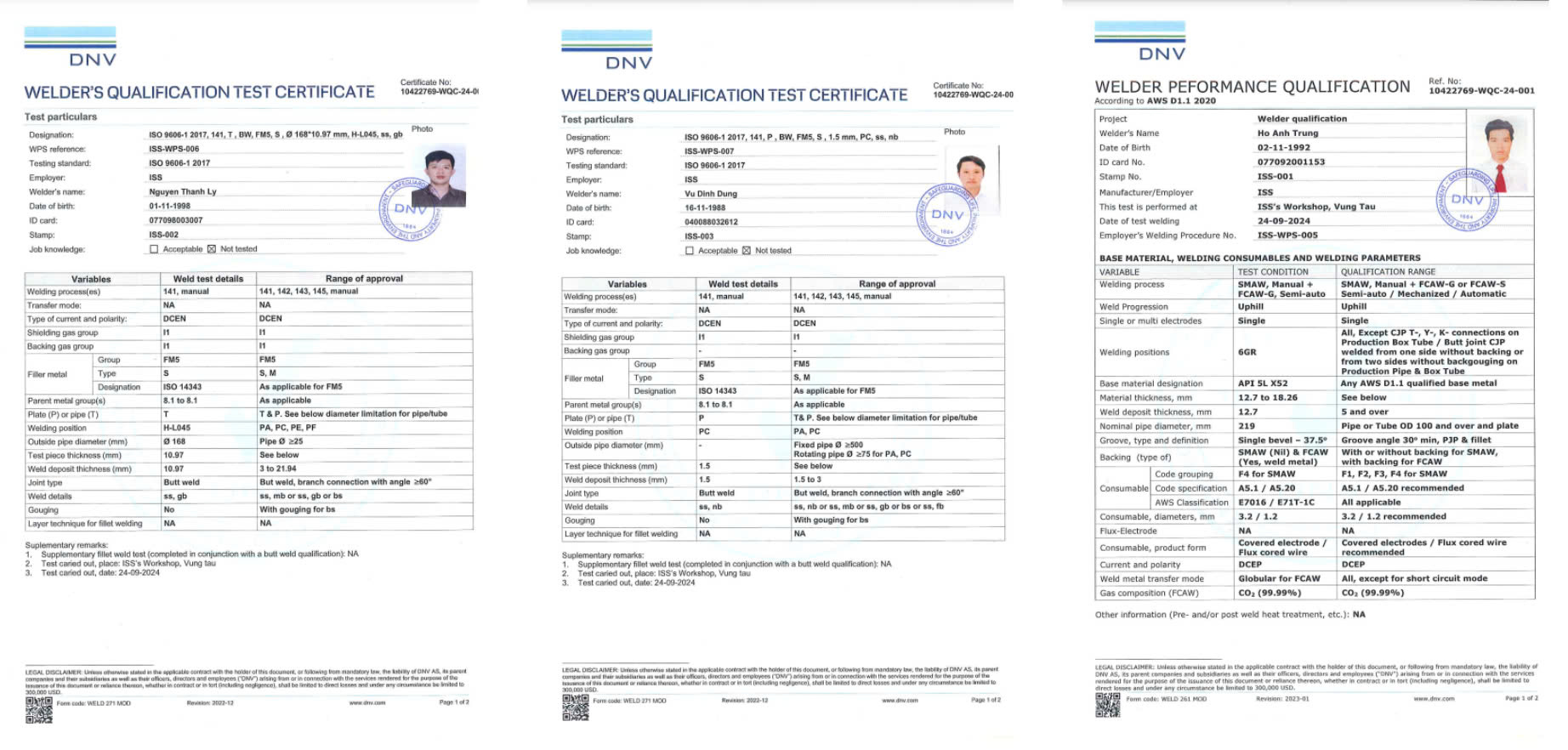

- Personnel Requirements: Welding Coordinator and Certified Welders.

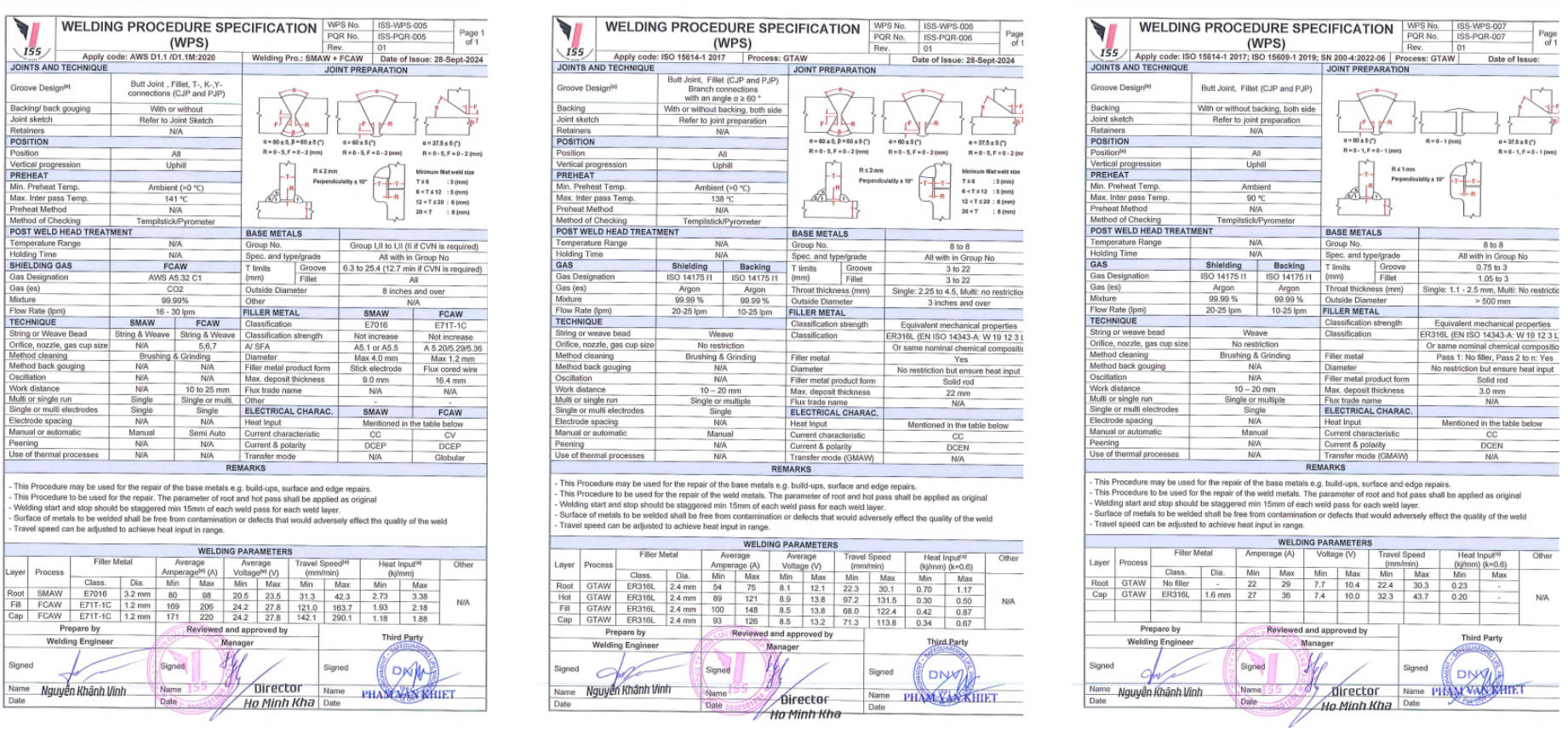

- Welding Procedures: follow strict Welding Procedure Specifications (WPS).

- Material Control: checks to meet the required specifications and are suitable for the welding process including traceability, certification, and storage.

- Inspection and Testing: non-destructive testing (NDT) and destructive testing methods to verify the quality of welds. This includes visual inspection, radiographic testing, ultrasonic testing, and mechanical testing

- Documentation: comprehensive documentation at every stage of the process, including welding procedures, welder qualifications, material certifications, inspection reports, and non-conformance reports

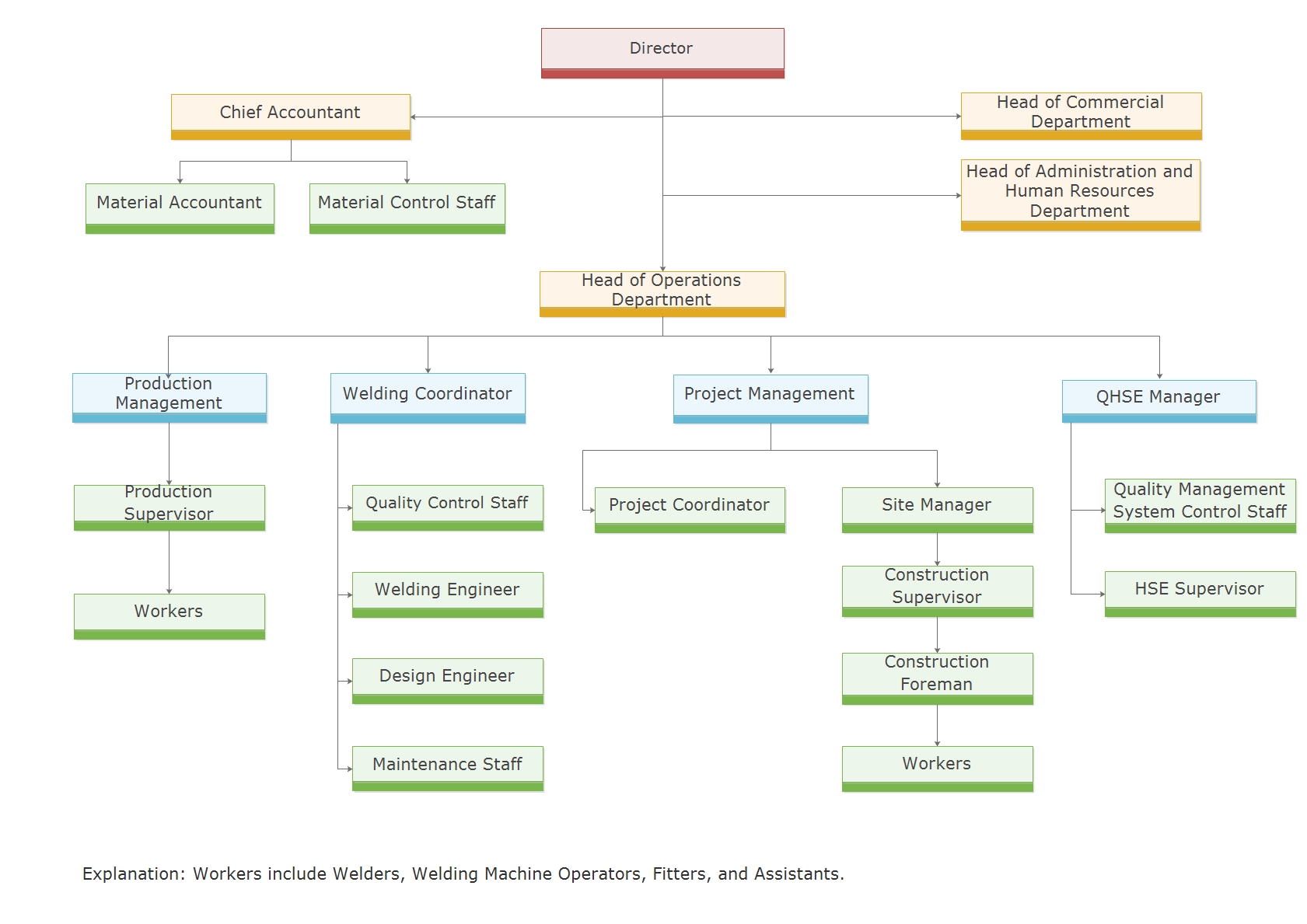

PERSONNEL REQUIREMENTS

ISS are complied with ISO 3834-2: Welding Coordinator and Certified Welders.

ISS are complied with ISO 3834-2:

Follow strict Welding Procedure Specifications (WPS)

- ISO 15614-1:2017 SN 200-4:2022-06

- AWS D1.1/D1.1M:2020

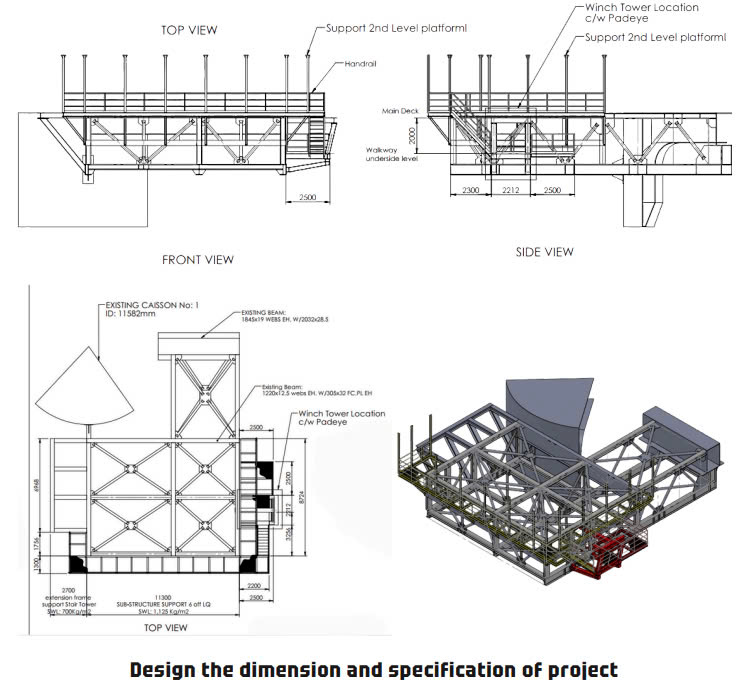

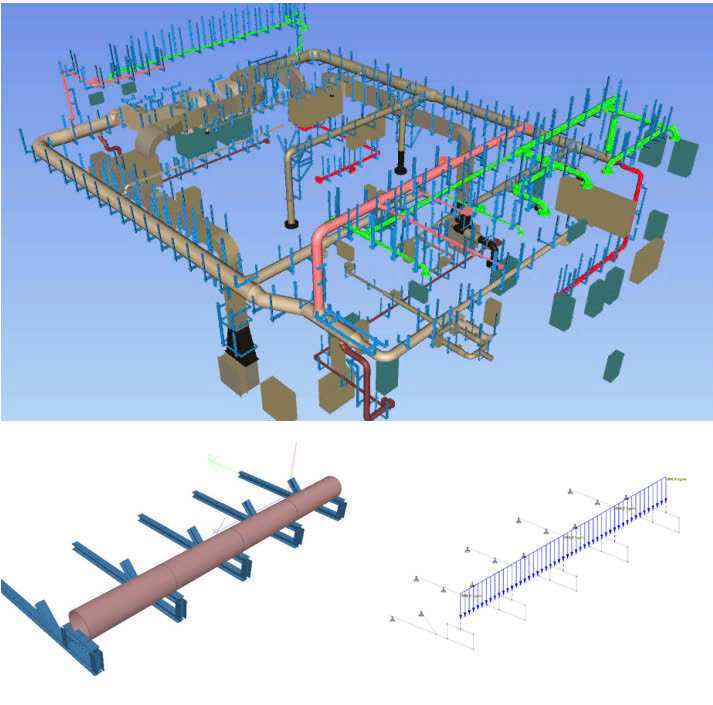

1.1. DESIGNATION & ENGINEERING

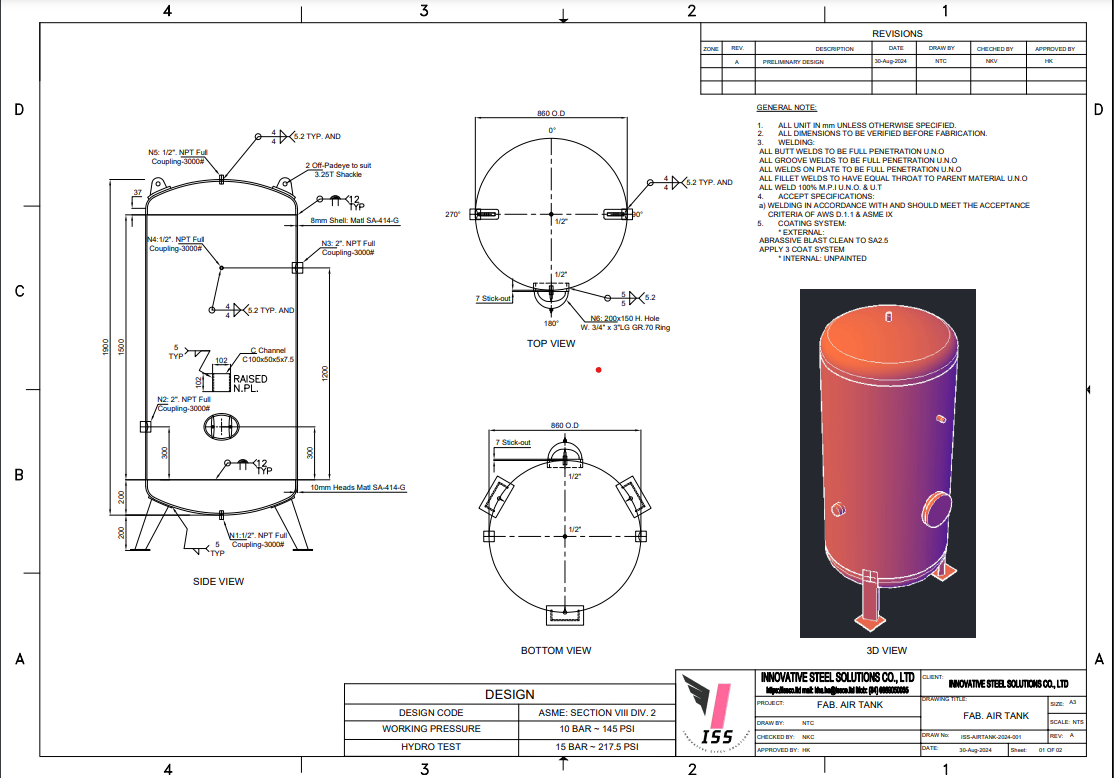

Designation is a vital process of assigning and specifying the materials, components, procedures, roles, and standards to ensure that the project is executed properly, and meets safety, quality, and regulatory requirements. This allows the engineering and construction team to communicate clearly and follow the same specifications, ensuring consistent results throughout the project.

We use various software programs: AutoCAD, SolidWorks, STAAD…

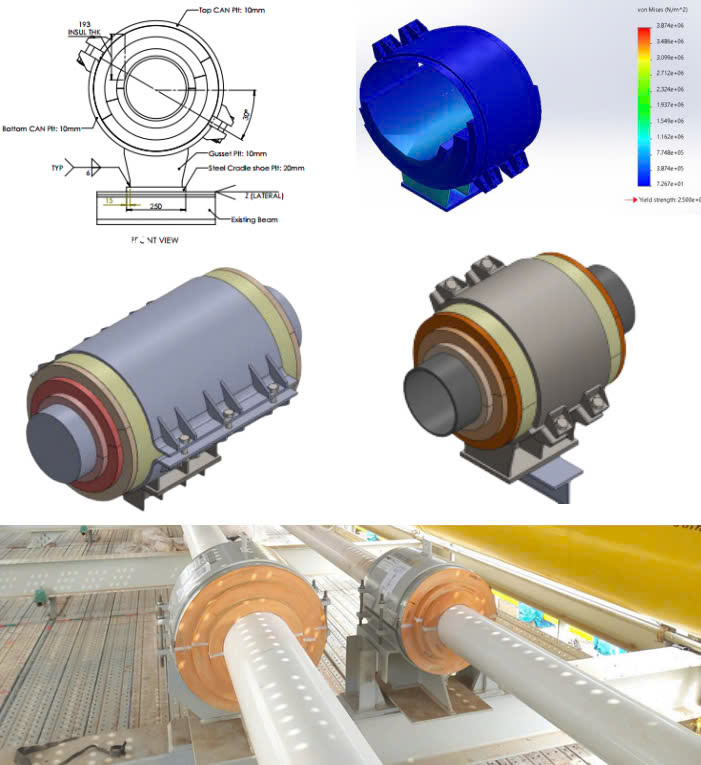

1.2. STEEL STRUCTURAL ANALYSIS

Steel structure analysis is a critical part of the design and engineering process for steel structures like cranes, tanks, vessels, bridges, buildings, industrial plants, and towers. The analysis helps ensure that a structure will support the intended loads, resist environmental factors, and remain safe throughout its lifetime.

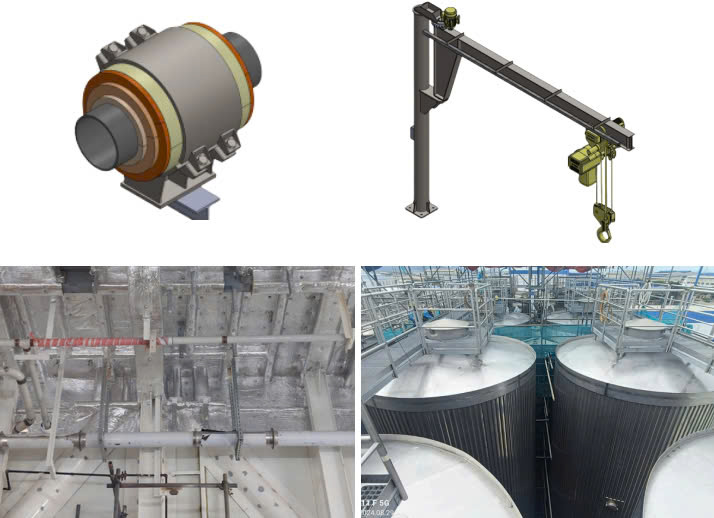

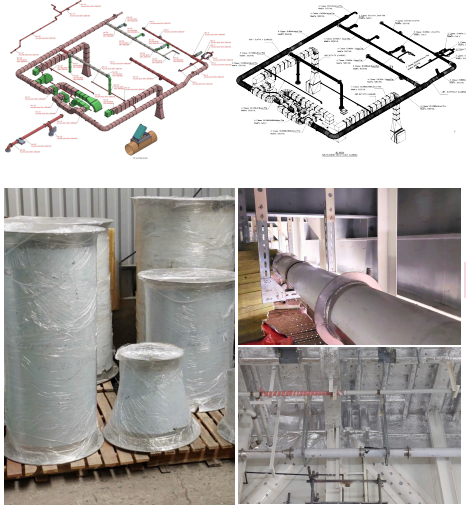

1.3. STEEL FABRICATION

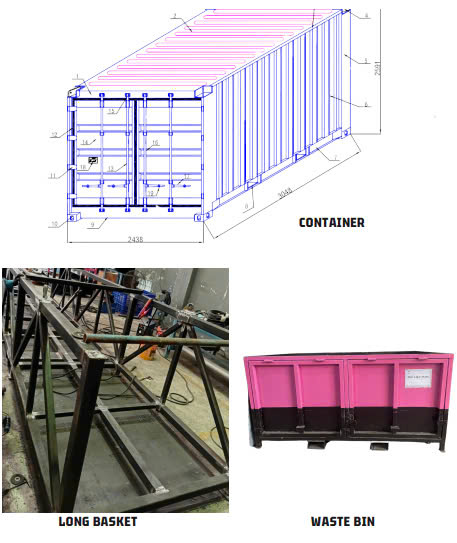

Steel fabrication services are essential for constructing strong, durable, safe steel structures across various industries. The fabrication process involves precise CNC cutting, bending, forming, welding, and assembling steel into cold pipe supports, cranes, tanks, HVAC systems, and skids….

With the use of advanced quality control measures ISO 9001: 2015, ISO 3834-2, EN 10204 – 3.2, and ISO 14001 standards, our turnkey projects are completed to the highest standards of quality, safety, and efficiency:

- Fabrication Steel Cold Pipe Support including insulation materials

- Cranes designation, engineering and fabrication

- HVACs designation, engineering and installation

- High pressure air tanks, beer tanks

Fabrication Steel Cold Pipe Support including insulation materials

Cranes designation, engineering and fabrication

HVACs designation, engineering and installation.

High pressure air tanks and Beer tank

Steel fabrication products meet Offshore standards

Steel fabrication products meet Offshore standards